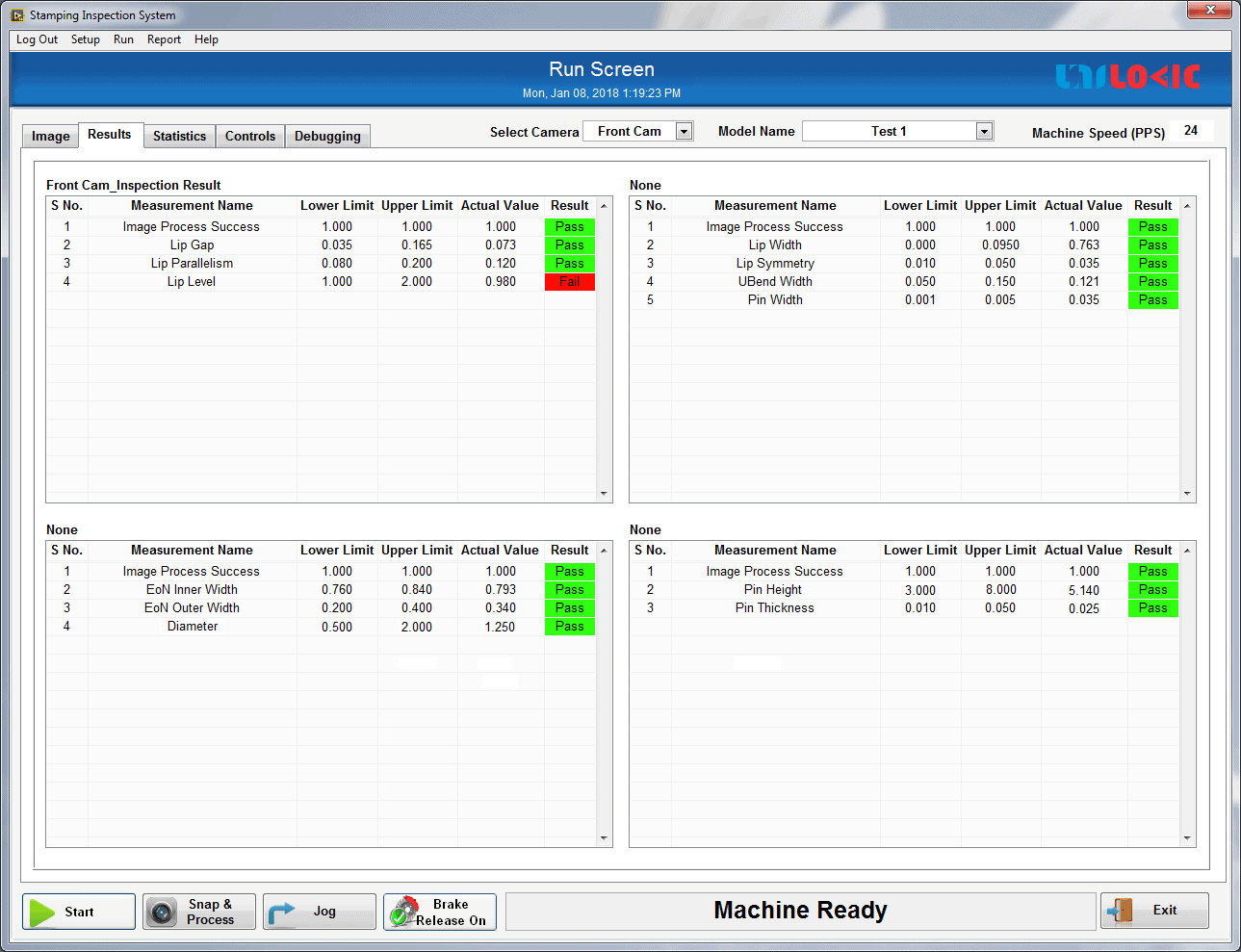

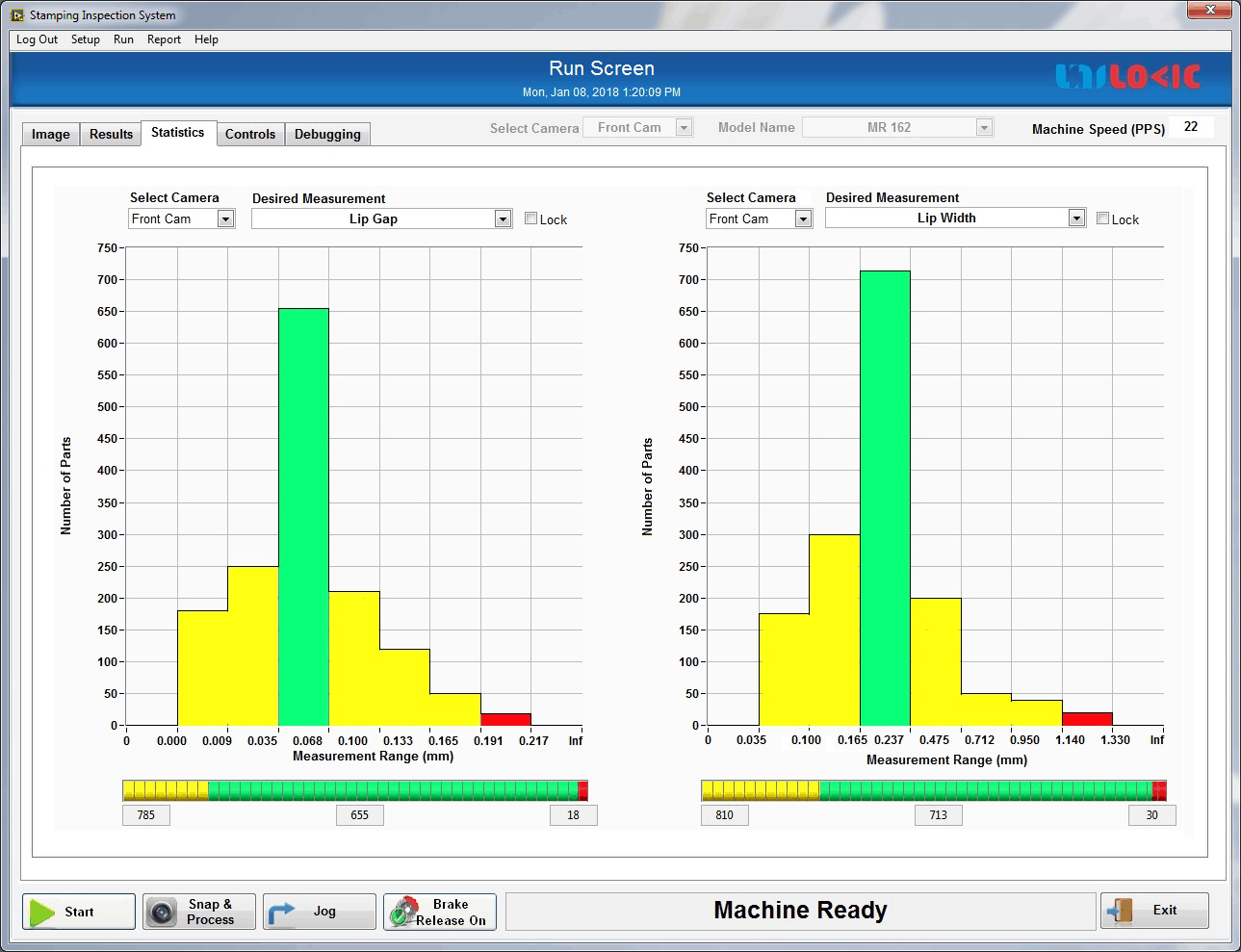

The reel coming out of the stamping machine will approximately have 12,000 contacts. Due to the continuous form of a reel and huge volume only 10 contacts samples were cut and manually inspected. Using our high-speed vision-based stamping inspection system, a reel will be directly fed and 100% online inspection will be done.

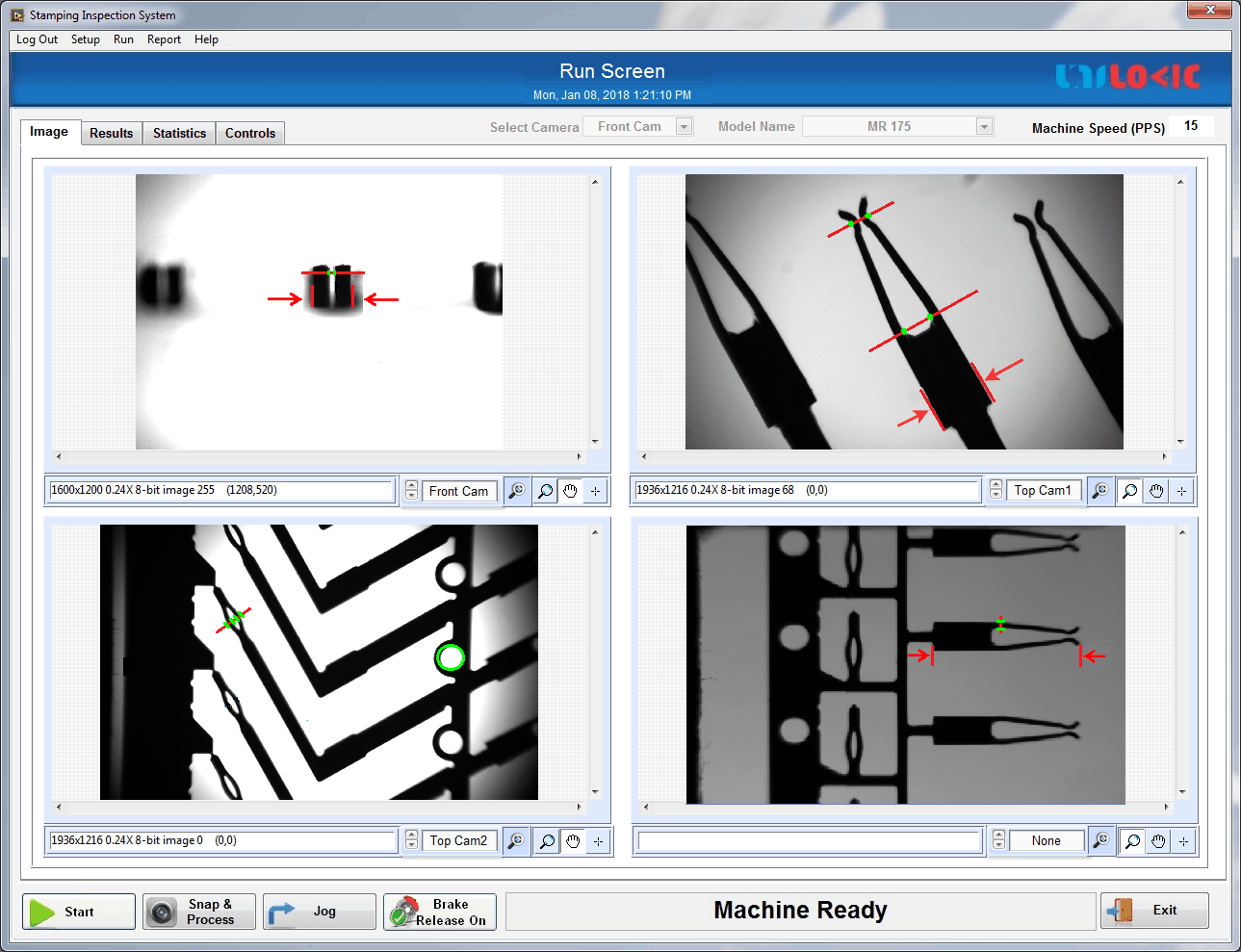

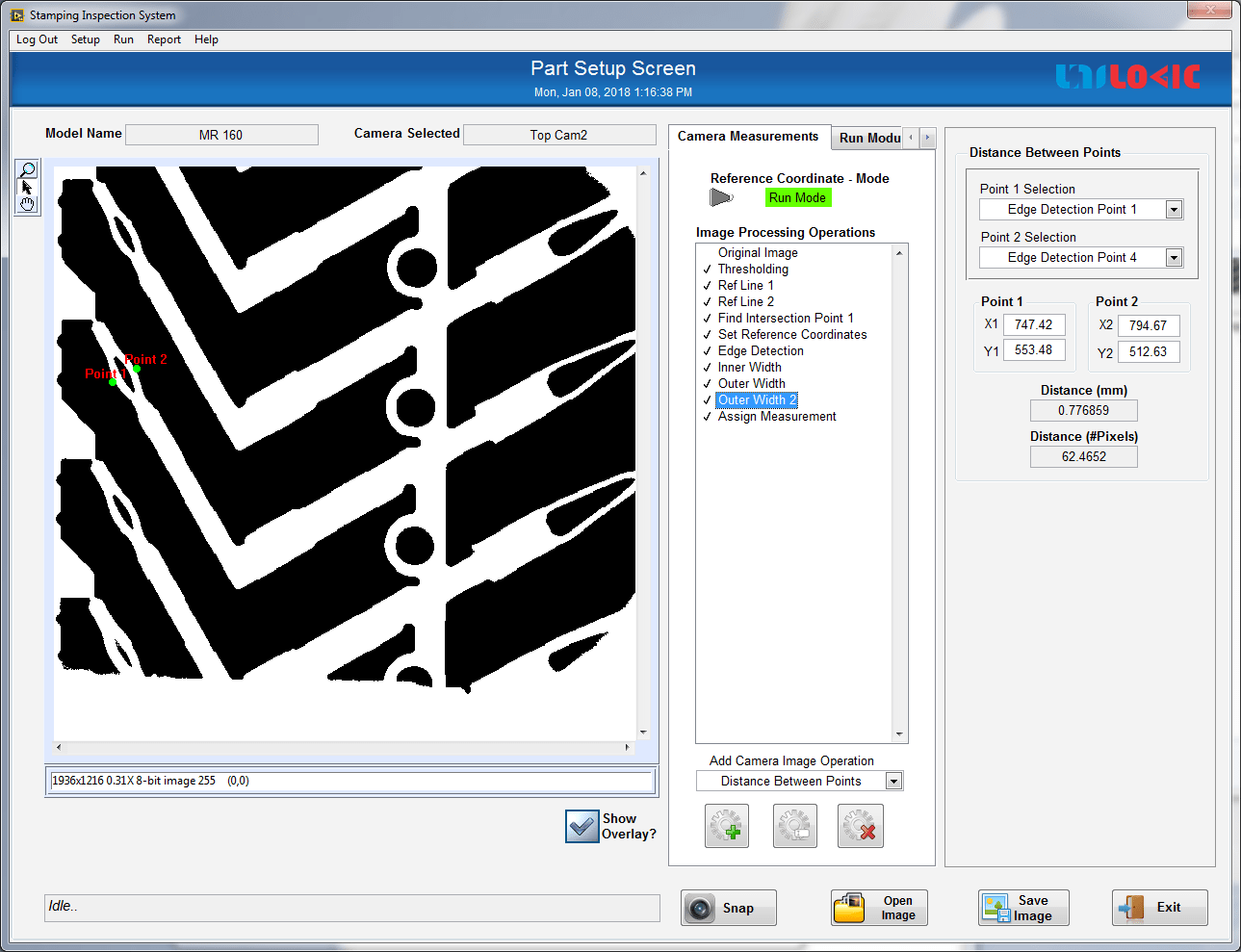

This machine has multiple cameras positioned in different views (Front, top etc.,.) to cover various dimensions and to identify possible contact damages. Maximum speed of the machine is 30 contacts per seconds and accuracy levels up to 5 µm. When the defective contact is identified, machine will automatically stop at that defective contact, so that the operator can cut and reload.