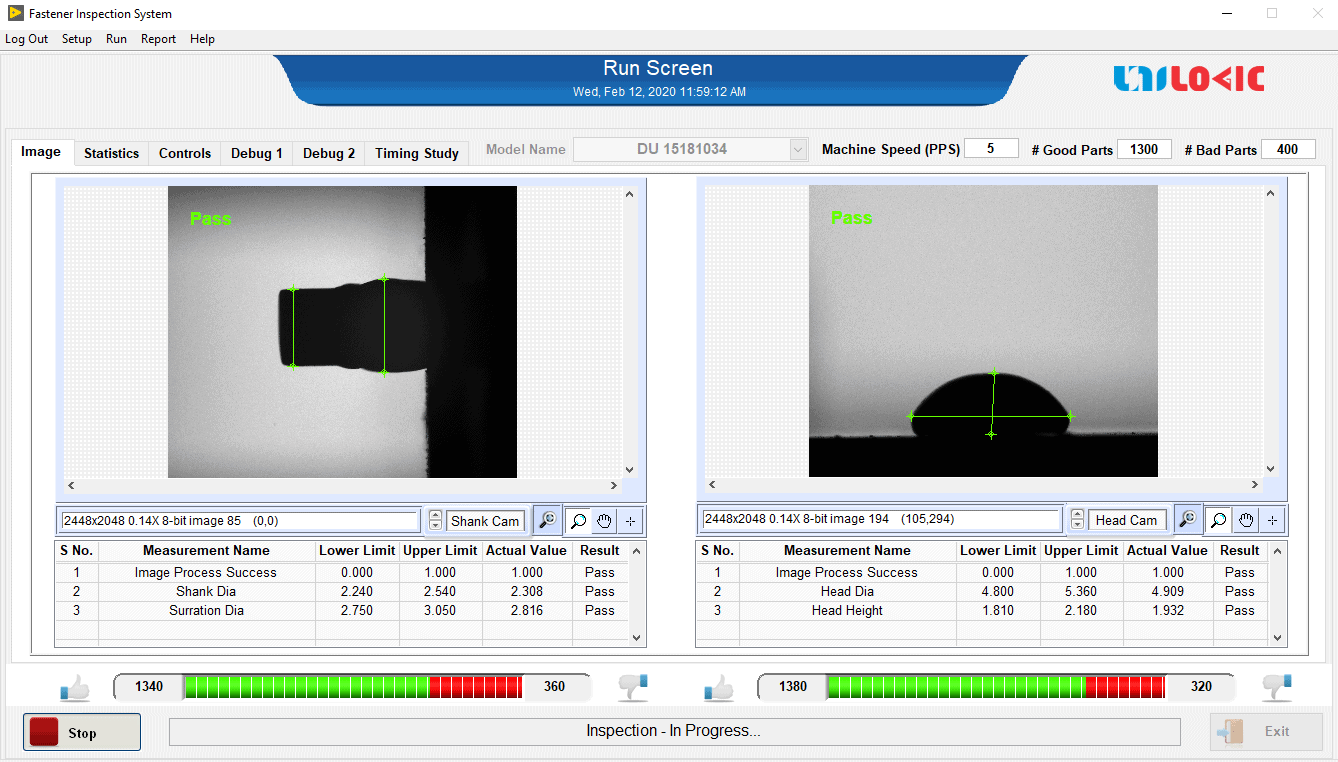

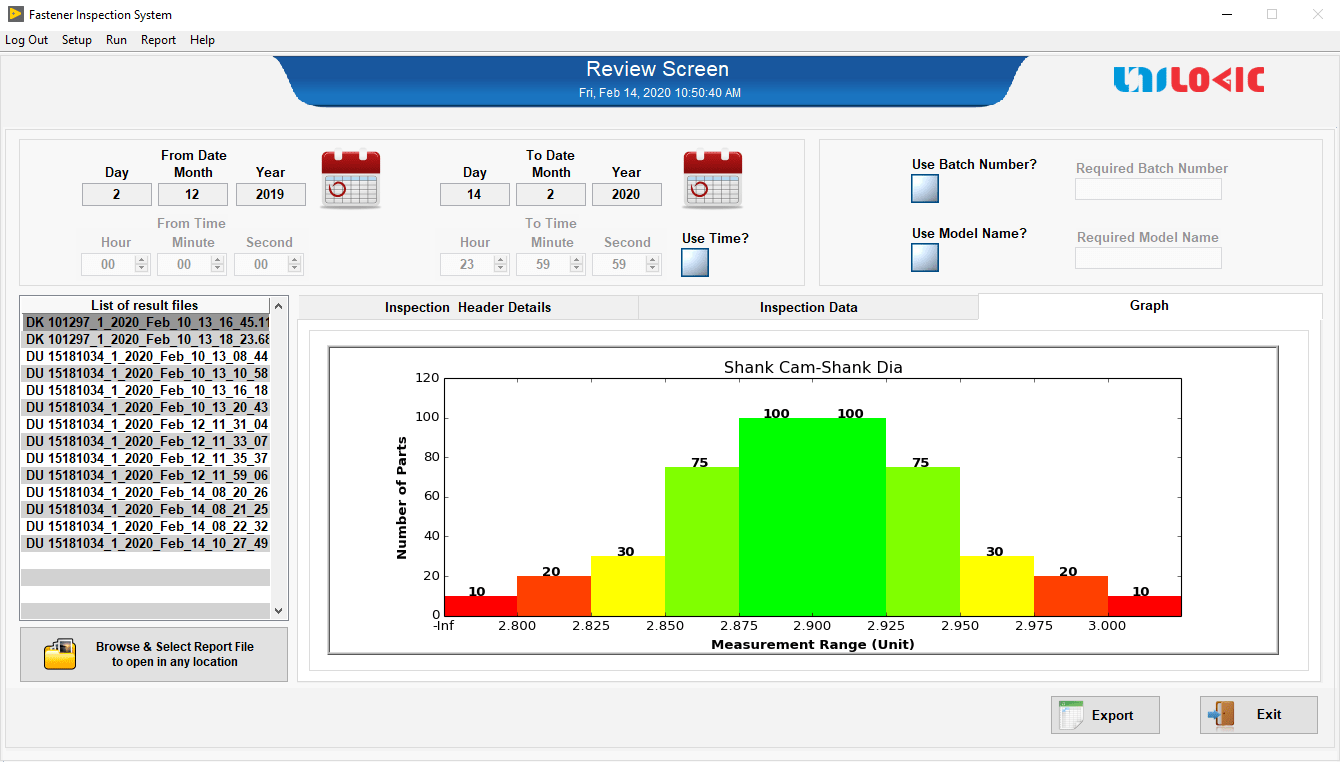

Our Fastener Inspection System (FIS) automates the inspection process with only one operator to load and collect segregated parts. FIS can measure dimensions like head diameter, shank diameter, shank length, thread length, etc., and defects like notches on peripheral, cracks on the surface, and other punching defects. It can detect the rivet colour and identifies the symbol.

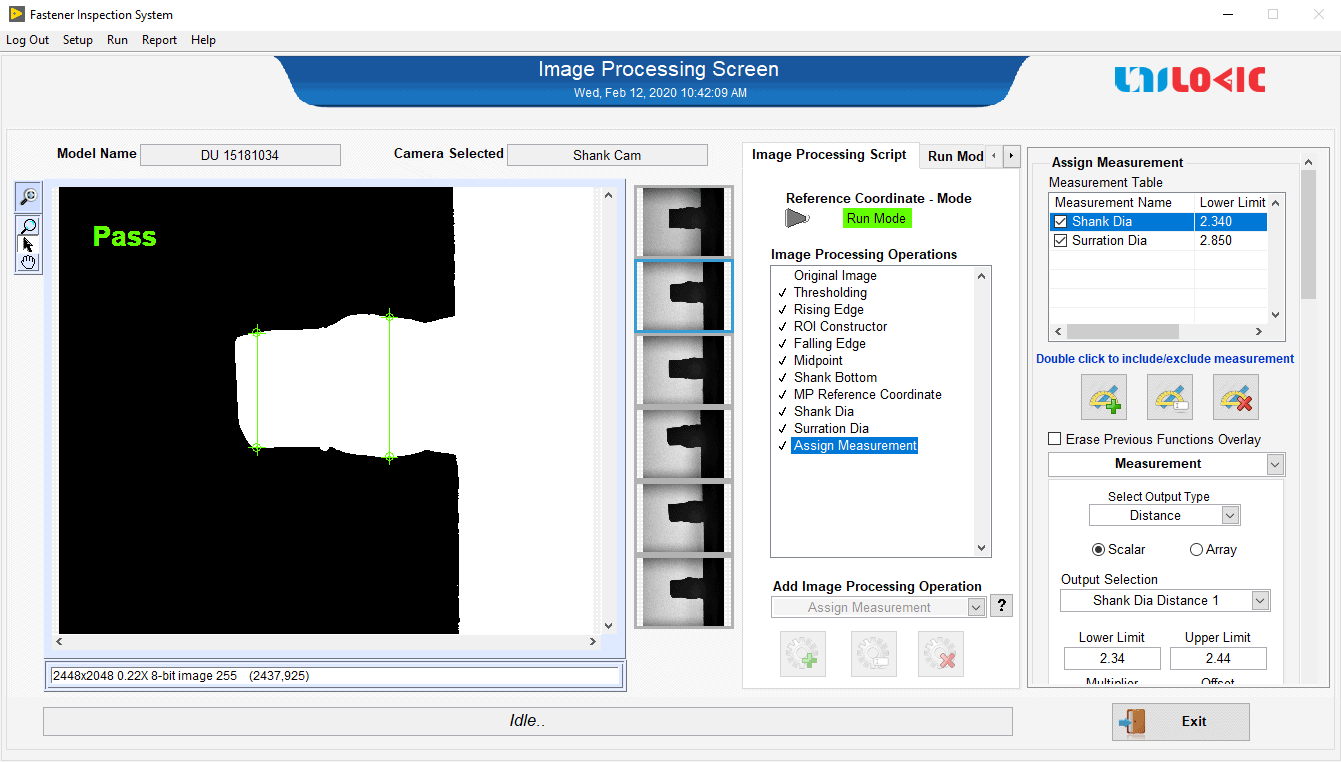

The operator loads the fasteners to the vibratory bowl and fed to the system in an aligned manner and lands on the rotating disc. The image is captured from different angles and positions for analysis. The software will collect those images and apply image processing algorithms to differentiate accept (OK) and reject (Not OK) parts. Using Pneumatic ejectors, accepted/rejected parts will be collected in different bins.