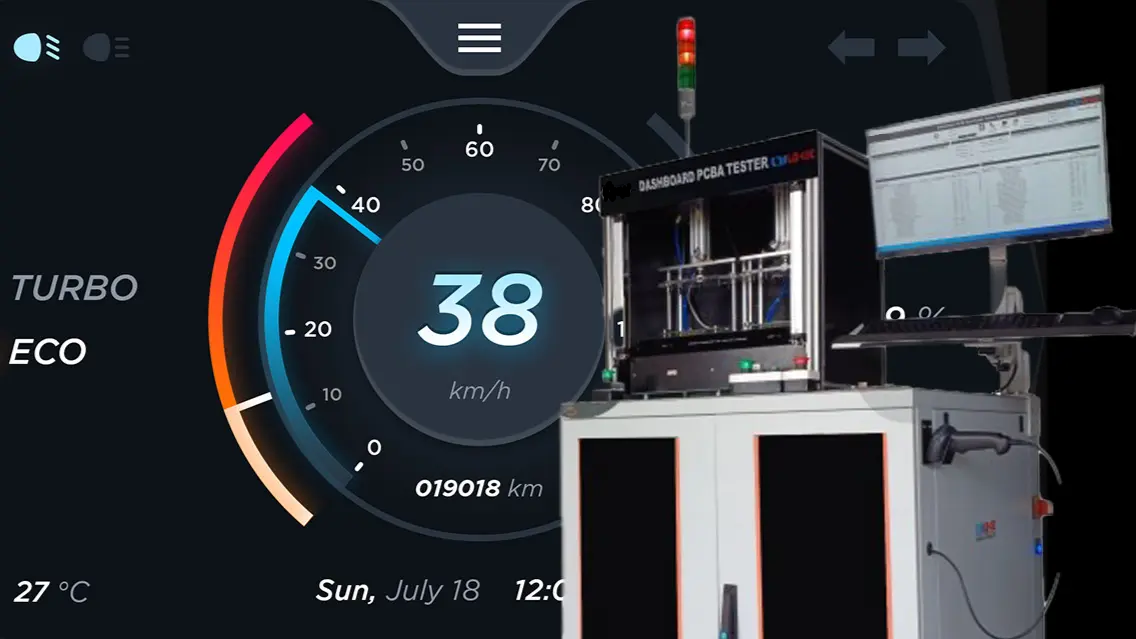

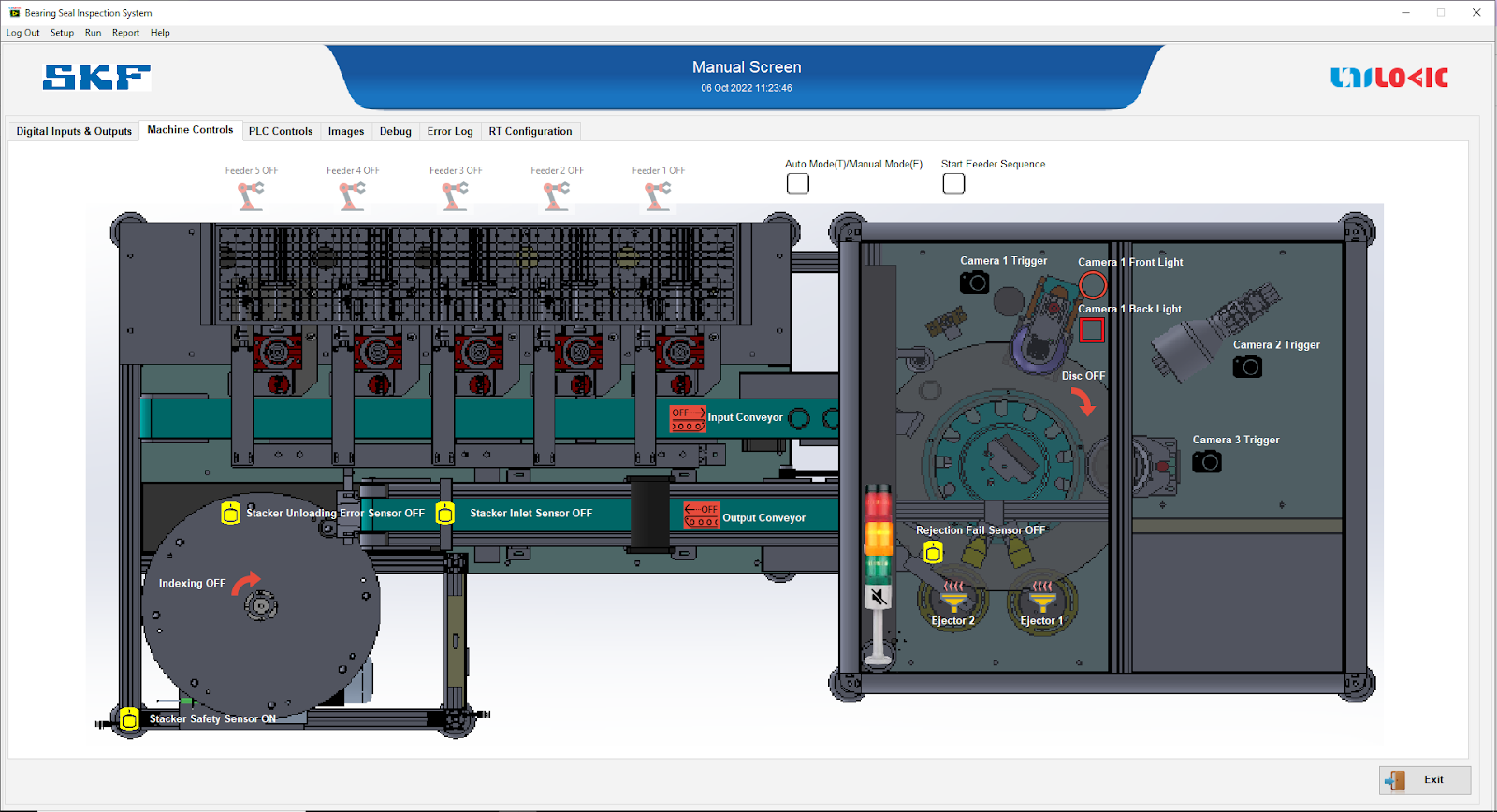

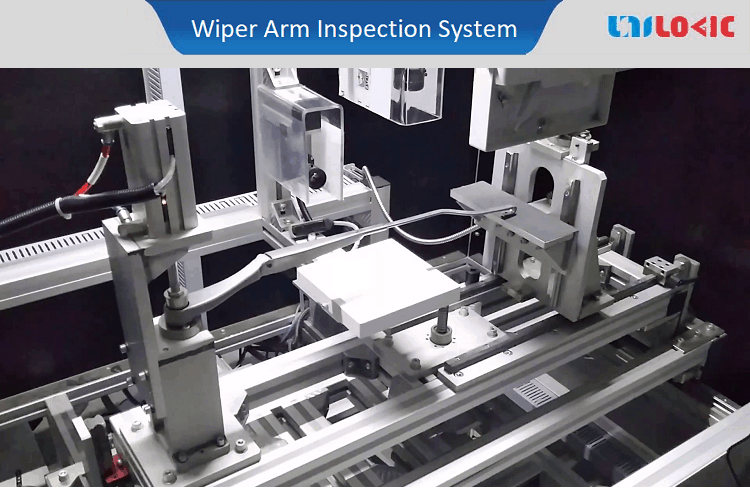

Functional Testing System for Load and Power Distribution Unit in EV

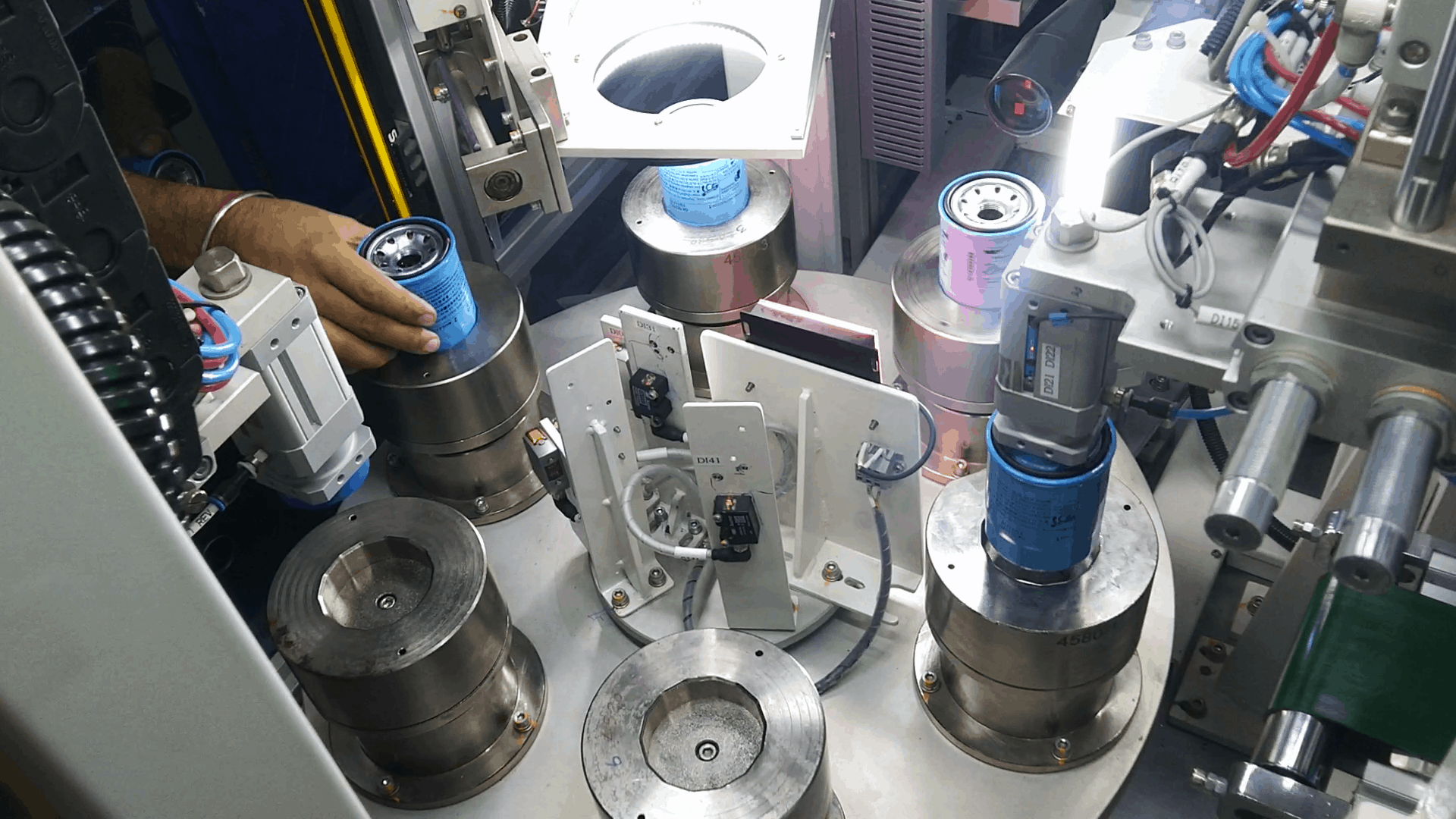

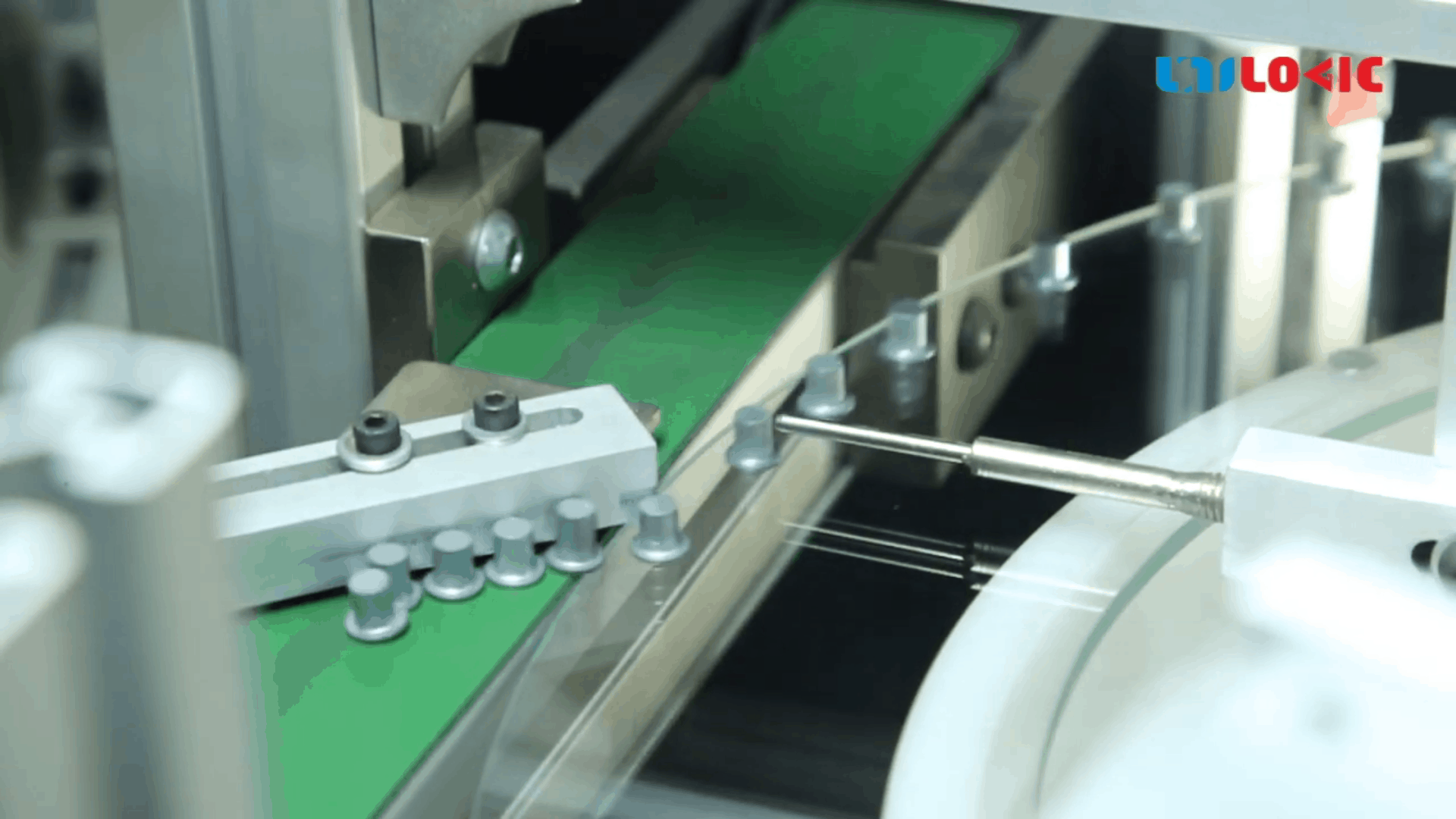

In the Electric Vehicle (EV) sector, the reliability of Load Distribution Units (LDU) and Power Distribution Units (PDU) is crucial. A leading EV manufacturer faced challenges in maintaining high quality while scaling production. We have developed a machine that tests up to 160 parts per hour.